Reports on production errors

The team of Daimler have generated automated reports on production errors that occur in the production machinery.

Reduced complexity

The software of AX Semantics serves to reduce the complexity of a very extensive data set and helps to find the most actionable pattern.

Useful tool

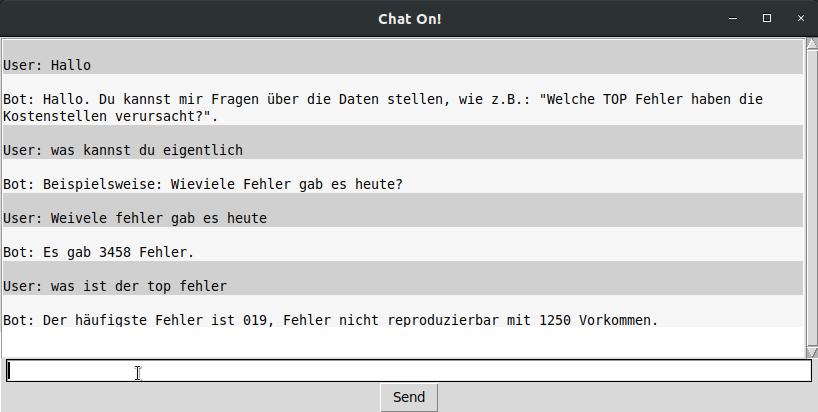

A new chat bot specifically helps to identify issues and problems quickly.

The Case

Daimler is one of the leading automobile manufacturers in the world. They produce thousands of cars, vans, trucks, and buses every year. This is done with the help of assembly lines. If an error occurs, and production is on hold, Daimler needs to react quickly - to save costs and to keep their tight schedule.

The Challenge

A quick overview of production errors as well as high quality and precise error reports are essential to guarantee a smooth production process. Therefore, it is fundamental that these reports are generated as quickly as soon as the error occurs. So Daimler needed to find a way to speed up the generation process of the error reportings.The Solution

The Daimler team knew they had to find a way to automate the entire process of the generation of error reports. That's why Daimler has automated their error reportings with the AX Semantics software. They also designed a chat bot, based on certain parameters, which gives a quick error reporting, if needed.

The Results

The software also helped with the reduction of the complexity of their very extensive data set. Therefore, it is easier to find the most actionable pattern. In addition, the chat bot helps engineers to locate errors and gives them a quick overview. The Daimler team can also ask the bot for details on specific issues.

Daimler

Daimler is a German car manufacturer who can trace back its history to the invention of the automobile itself. And yet, the company has been giving technical impulses for the world's car market ever since. Next to cars, Daimler also manufactures vans, buses and trucks. The company counts more than 170,000 employees on five continents. ![Daimler-800x800[1]](https://www.ax-semantics.com/hs-fs/hubfs/1_Website%20Migration%202024/Landingpages/Client-Logos/Daimler-800x800%5B1%5D.png?width=189&height=189&name=Daimler-800x800%5B1%5D.png)

.png?width=1080&height=1080&name=Daimler%20(1).png)